Certified Company

ISO 45001:2018 | ISO 9001:2015Gas Induction Reactors

Highlights

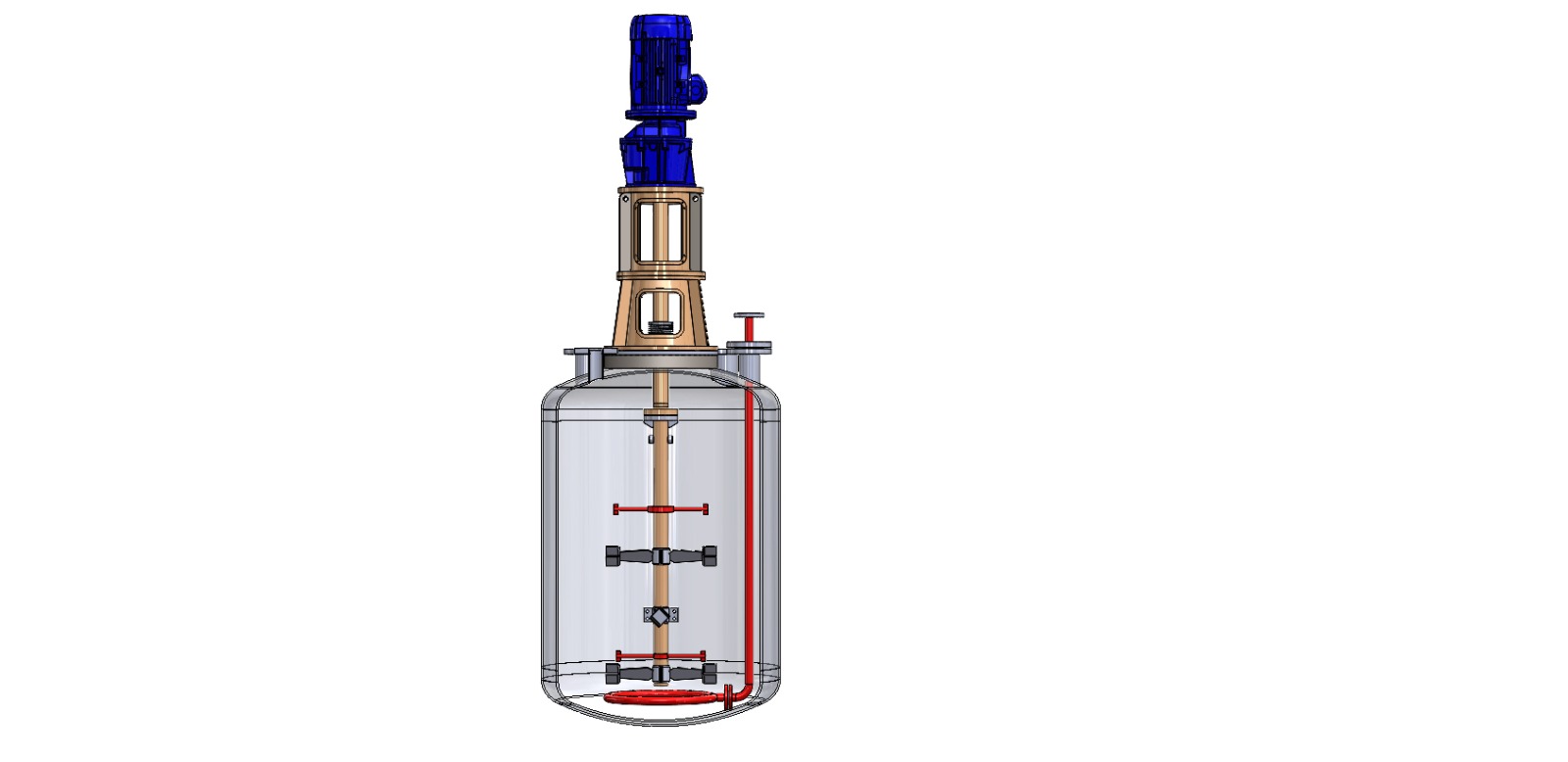

Gas Induction Reactor offers a radical change from all the conventional approaches, Instead of churning the liquid reaction mass, a hollow agitator pumps gases from the head space to the lowest part of the reactor vessel, A specially designed impeller vigorously disperses these gases into the reactor bottom, resulting in a mixture akin to a boiling liquid, Gas bubbles react with liquid/slurry as they rise; Unreacted gases are re-induced into the liquid.

The Self-aspiration agitator of an Gas-Induction Reactor has a highly efficient design, which leads to the following advantages:

-

Vigorous gas mixing

-

Through suspension of solid components (e.g., Catalyst)

-

Large Gas-Liquid interfacial areas. Interfacial area is 100 to 300m3 of the operating volume

-

Enhanced gas-liquid and liquid mass transfer rates

-

Very high vessel side heat transfer coefficients, which approach boiling coefficients

-

Reduced batch times

-

Minimal side reactions

-

Excellent batch to batch repeatability.

Maximum Manufacuring Capacity

- Standard Capacity Model upto 35 Kg pressure

Material of Construction

- SS 304 / SS 316L / SS 317 / SS 321 / 904L

- Hastelloy C276 / Inconel 625

- Duplex UNS31803 / Super Duplex UNS327